BaiChuan Precision — Your trusted CNC machine shop

Precision machining gathers steam to drive automotive, electronics, and many other industries forward. It’s a time- and money-saving production technique that allows you to churn out parts and ensure consistency in every single detail. Would you like to turn precision machining to your advantage? China’s major CNC machine shop is at your service.

Welcome to BaiChuan Precision! Our professional team has over 25 years of experience in high-grade CNC-machined product manufacturing. There are no impossible tasks for us as BaiChuan Precision’s state-of-the-art facility boasts over 20 CNC machining centers for 3-axis, 4-axis, and gantry machining. The expertise that we’ve developed so far empowers us to be at the forefront of CNC processes and help you produce top-quality parts.

Make the most of advanced CNC machining at BaiChuan Precision

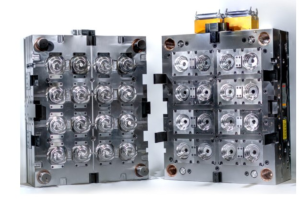

Precision CNC machining requires top-notch equipment and skilled specialists who know how to use them. At BaiChuan Precision, we draw on our 25-year experience to kick our processes into high gear as a leading CNC machine parts manufacturer. We specialize in a range of services, from prototyping to end-product reverse engineering and mold processing, to meet your production needs.

With our CNC machining services, you can benefit from:

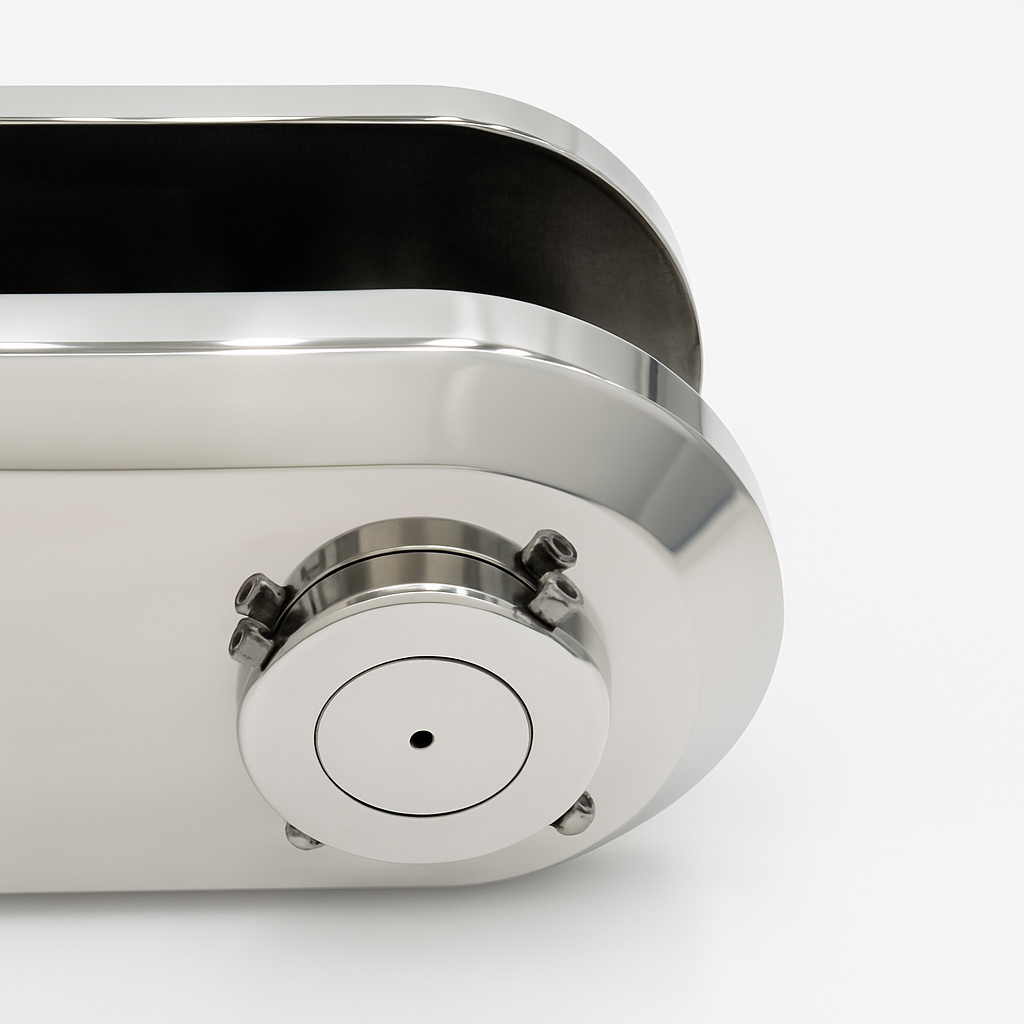

- High precision. We can create microstructures and process thin, fragile parts thanks to the fantastic accuracy of our CNC machines.

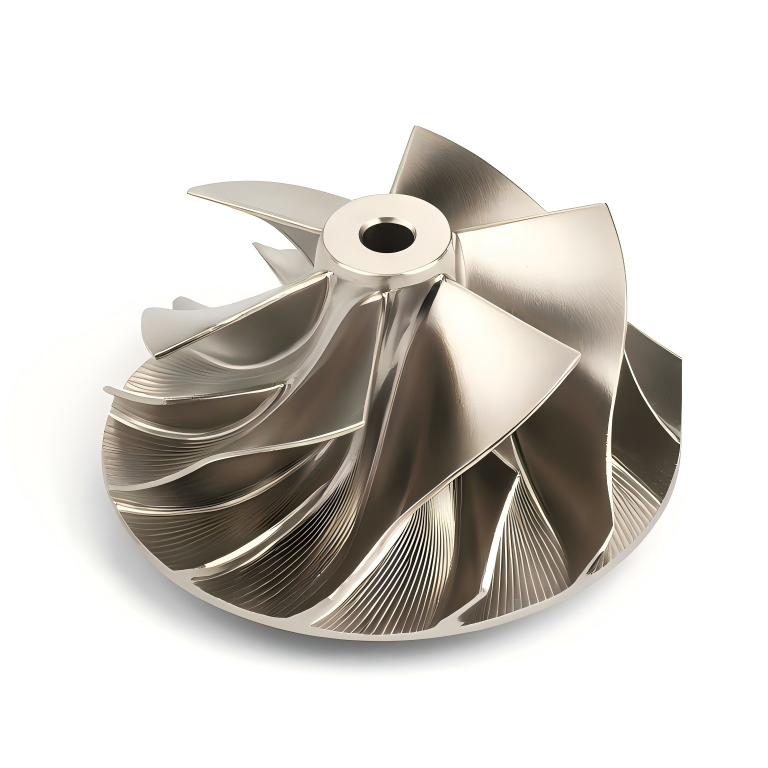

- Design flexibility. Computer-controlled processing allows us to go beyond design limits. We can deal with any shape and contour based on your product drawings.

- Surface integrity. With us, you can also get your parts flawlessly finished. We will then check them using a microscope, hardness gauge, and other specialized equipment.

- Production efficiency. When getting your parts machined with BaiChuan Precision, you can save money on every production run. Thanks to automated processes, we deliver substantial production savings for your business. As a famed CNC machining service provider, we use high-performance equipment for faster turnaround times and reduced human error.

We can take on any order and produce complex parts with any design features. Provide us with your drawings or samples, and we’ll do the rest.

Short-run and long-run production

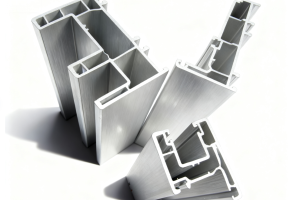

The BaiChuan Precision CNC milling factory is built to prioritize high technological capacity and flexibility. The latter allows you to start a production run of any volume and for any parts. Even if you need metal CNC milling and drilling service for fewer than 500 pieces, we can do it without additional small order fees. This applies to parts made of titanium, aluminum, stainless steel, and other metals and to any extra service like surface finishing.

It doesn’t take weeks or months to reconfigure our CNC milling shop and CNC machining centers for short production runs. With multi-axis equipment and adjustable work envelopes, we can get down to creating your parts as soon as we agree upon design features and handle transaction details. In most cases, you’ll receive your CNC-machined pieces qualifying for short-run production within 20-30 days.

Long-run production orders can get from design consultation to CNC precision milling machines just as fast as short runs. The lead time will depend on what pieces you need, whether additional services are required, and how many metal parts you want us to produce.

Product surface finished your way

No production run and parts are complete without making them look and function the way you need. At BaiChuan Precision, we can finish the surface of your items for your aesthetic requirements or industry standard compliance following the CNC milling service. Whether you need to modify the texture of your pieces or strengthen some product characteristics, our finishing options include:

- Electroplating and electroless plating

- Vacuum plating

- Anodic oxidation

- Hot-dip galvanizing

- Chemical treatment

- Thermal spraying

- Painting

The required surface finish for your metal parts should be discussed with BaiChuan Precision specialists as you place your order. You will need to share as detailed information about the desired surface treatment as you can, along with the product specifications we will use during your production runs.

Leave your order for CNC parts online and get a quote

Whether you require CNC machining or reverse engineering services, BaiChuan Precision will eagerly meet your needs. Our savvy specialists can create machine parts based on your custom drawings or provide you with new ones.

Let us take your production up a notch, regardless of your location. BaiChuan Precision provides CNC machining services in China and far beyond its borders while handling the process until your goods are shipped. We work with such international express delivery services as DHL, FedEx, and UPS so that you get your samples in no time through couriers or sea shipping companies.

BaiChuan Precision is looking forward to helping you every step of the product creation way. Contact us to discuss what CNC services are best for your parts and get a quote.

![注塑 改 {"source_type":"douyin_beauty_me","data":{"product":"retouch","effect_type":"tool","capability_key":["portrait","sticker","edit","erase"],"stickerId":"","os":"ios","appversion":"13.2.0","effect_id":"portrait","filterId":"","imageEffectId":"","enter_from":"enter_launch","pictureId":"F8822014-2C2F-4ECA-8EC0-DB3176078AF9","capability_extra_v2":{"edit":[{"panel":"local_adjustment"}],"erase":[{"panel":"eliminatePen"}],"sticker":[{"effect_id":"????????","panel":"sticker"},{"panel":"sticker","effect_id":"??????"}]},"activityName":"","infoStickerId":"????????,??????","playId":""}}](https://bccncmilling.com/wp-content/uploads/elementor/thumbs/注塑-改-rd6jtv2jpmucil6ar0wba8xacddr4ytcjw2l9cdej4.jpg)